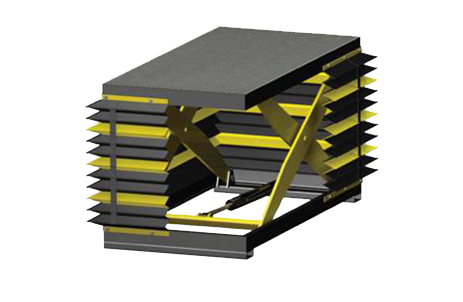

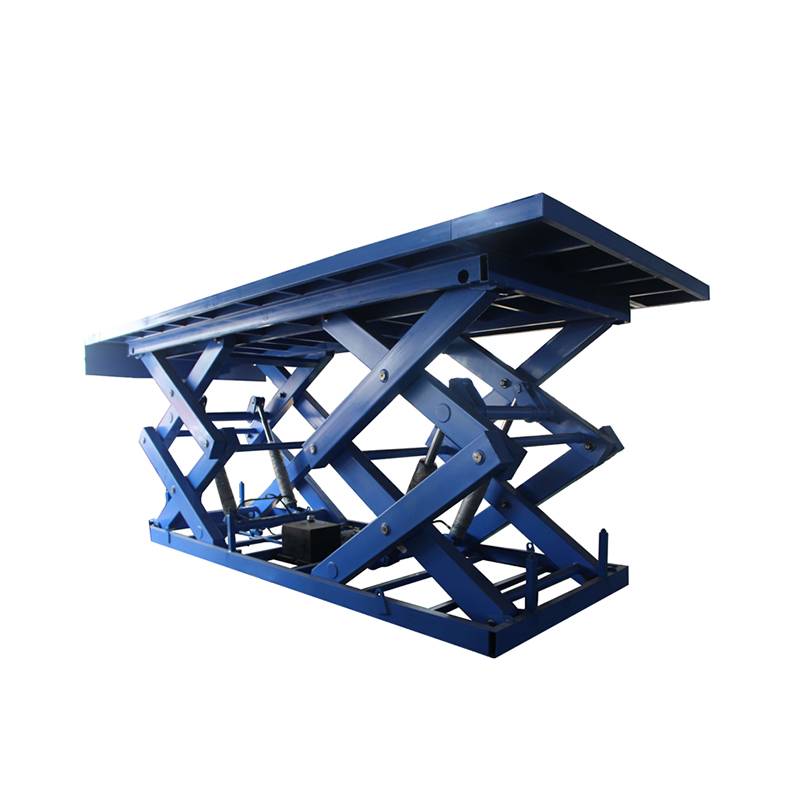

Single Scissor Lift Table

China Scissor Lift Table is popular in warehouse work and Automatic Conveyor work , there is many different type lift table offer to select.Besides,there is many installation method about how to install scissor lift platform,put it on ground directly or make a pit to become pit scissor lift table.

We have design many safety configuration for our Scissor Table Lift which include anti pinich function,overload protection,self lubricating bearings and safety below and so on. As a leading enterprise in China's leading logistics handling industry, we are worthy of being trusted and chosen.Contact us to get a quotation which will satisfy you !

FAQ

A:Our scissor lift table has got ISO9001 and CE certificate already which is best quality lift table in China.We guarantee it can be used more than 10 years.

A:Our scissor lift table adopt Standardized production which will reduce a lot of production cost.So our price will be so competitive,meanwhile guarantee quality of our scissor lift table.

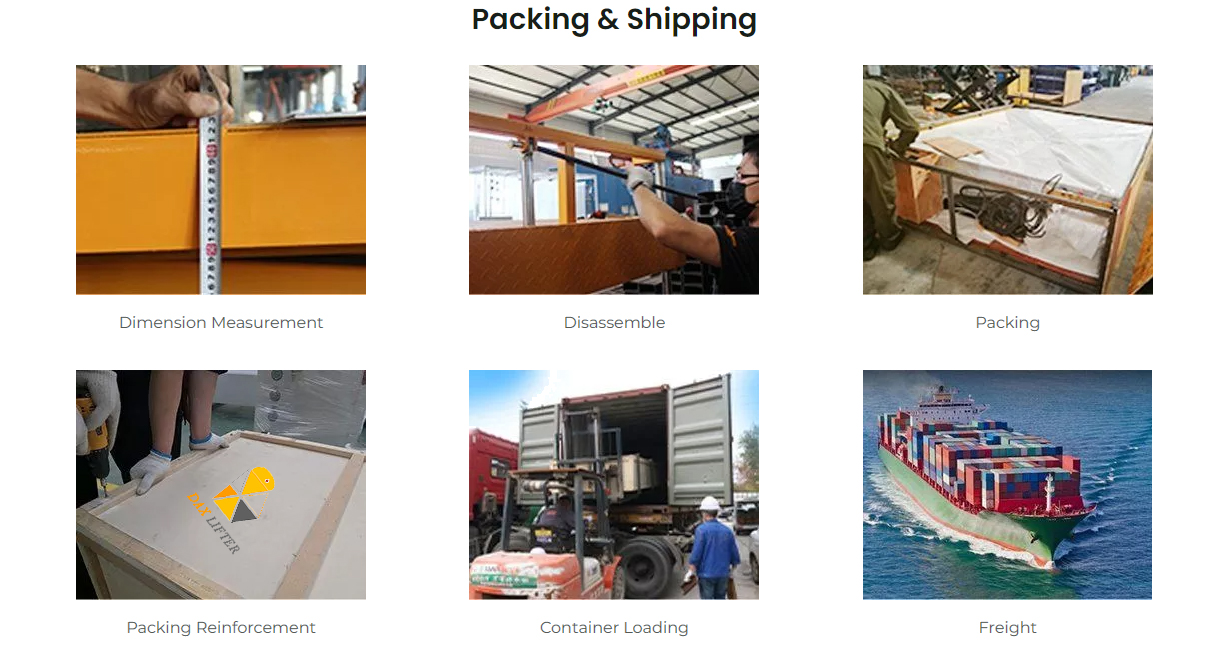

A:We have cooperated with powerful shipping company for many year who will offer economic shipping price to us and offer best shipping service.

A:We shall offer 12 months warranty time with free spare parts. Meanwhile offer long term technical support and charged parts once warranty time over.

Video

Specifications

|

Model |

Load Capacity (KG) |

Self Height (MM) |

Travel Height (MM) |

Platform Size(MM) L×W |

Base Size (MM) L×W |

Lifting time (S) |

Voltage (V) |

Motor (KW) |

Net weight (KG) |

||

|

1000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX1001 |

1000 |

205 |

1000 |

1300×820 |

1240×640 |

20~25 |

As per your request |

1.1 |

160 |

||

|

DX1002 |

1000 |

205 |

1000 |

1600×1000 |

1240×640 |

20~25 |

1.1 |

186 |

|||

|

DX1003 |

1000 |

240 |

1300 |

1700×850 |

1580×640 |

30~35 |

1.1 |

200 |

|||

|

DX1004 |

1000 |

240 |

1300 |

1700×1000 |

1580×640 |

30~35 |

1.1 |

210 |

|||

|

DX1005 |

1000 |

240 |

1300 |

2000×850 |

1580×640 |

30~35 |

1.1 |

212 |

|||

|

DX1006 |

1000 |

240 |

1300 |

2000×1000 |

1580×640 |

30~35 |

1.1 |

223 |

|||

|

DX1007 |

1000 |

240 |

1300 |

1700×1500 |

1580×1320 |

30~35 |

1.1 |

365 |

|||

|

DX1008 |

1000 |

240 |

1300 |

2000×1700 |

1580×1320 |

30~35 |

1.1 |

430 |

|||

|

2000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX2001 |

2000 |

230 |

1000 |

1300×850 |

1220×785 |

20~25 |

As per your request |

1.5 |

235 |

||

|

DX2002 |

2000 |

230 |

1050 |

1600×1000 |

1280×785 |

20~25 |

1.5 |

268 |

|||

|

DX2003 |

2000 |

250 |

1300 |

1700×850 |

1600×785 |

25~35 |

2.2 |

289 |

|||

|

DX2004 |

2000 |

250 |

1300 |

1700×1000 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DX2005 |

2000 |

250 |

1300 |

2000×850 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DX2006 |

2000 |

250 |

1300 |

2000×1000 |

1600×785 |

25~35 |

2.2 |

315 |

|||

|

DX2007 |

2000 |

250 |

1400 |

1700×1500 |

1600×1435 |

25~35 |

2.2 |

415 |

|||

|

DX2008 |

2000 |

250 |

1400 |

2000×1800 |

1600×1435 |

25~35 |

2.2 |

500 |

|||

|

4000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX4001 |

4000 |

240 |

1050 |

1700×1200 |

1600×900 |

30~40 |

As per your request |

2.2 |

375 |

||

|

DX4002 |

4000 |

240 |

1050 |

2000×1200 |

1600×900 |

30~40 |

2.2 |

405 |

|||

|

DX4003 |

4000 |

300 |

1400 |

2000×1000 |

1980×900 |

35~40 |

2.2 |

470 |

|||

|

DX4004 |

4000 |

300 |

1400 |

2000×1200 |

1980×900 |

35~40 |

2.2 |

490 |

|||

|

DX4005 |

4000 |

300 |

1400 |

2200×1000 |

2000×900 |

35~40 |

2.2 |

480 |

|||

|

DX4006 |

4000 |

300 |

1400 |

2200×1200 |

2000×900 |

35~40 |

2.2 |

505 |

|||

|

DX4007 |

4000 |

350 |

1300 |

1700×1500 |

1620×1400 |

35~40 |

2.2 |

570 |

|||

|

DX4008 |

4000 |

350 |

1300 |

2200×1800 |

1620×1400 |

35~40 |

2.2 |

655 |

|||

Advantages

High-quality Surface Treatment:

In order to ensure the long service life of the equipment, the surface of our single scissor lift has been treated with shot blasting and baking paint.

High-quality Hydraulic Power Unit:

Because our equipment uses high-quality pumping station units, the electric lift is more stable and safer during use.

Simple Structure:

Our equipment has a simple structure and it is easy to install.

Equipped With Flow Control Valve:

Lifting machinery is equipped with a flow control valve, which allows its speed to be controlled during the descending process.

Explosion-proof Valve Design:

In the design of the mechanical lifter, a protective hydraulic pipeline is added to prevent the hydraulic pipeline from rupturing.

Application

China Stationary Scissor Lift Table are widely used in various production workshops, assembly line production and warehouse handling industries.

Case 1:

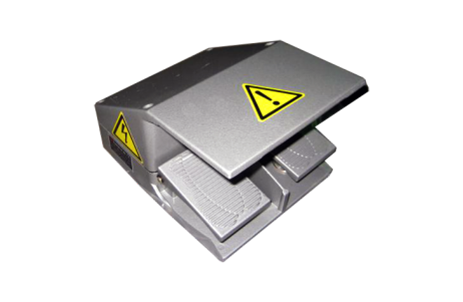

Our New Zealand customer purchased our fixed lift table for the wood production line conveyor, and he chose a roller platform option, so that the wood can be transported down the production line more efficiently and conveniently. The option of Roller platform we can choose different sizes of rollers according to customer requirements to meet customer needs. In addition, he also chose foot control, because the workers are standing on a fixed position of the assembly line. Through the foot control, the workers can free their hands to operate the assembly line and adjust the wood on the assembly line.

Case 2:

Our Saudi Arabia customer purchases our electric lift table for the handling and loading and unloading of food warehouses. Through our hydraulic lift table, the food boxes are removed from the transport truck and the food boxes are loaded from the warehouse to the transport truck. Through our fixed scissor lift table, work efficiency can be improved and workers' work easier.

Details

|

Control Handle Switch |

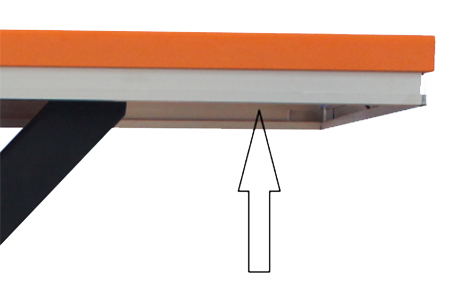

Automatic Aluminum Safety Sensor for Anti-pinch |

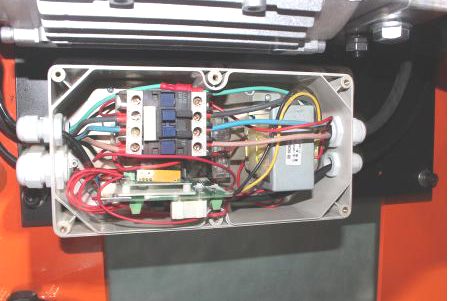

Electric Pump Station and Electric Motor |

|

|

|

|

|

Electric Cabinet |

Hydraulic Cylinder |

Package |

|

|

|

|

|

1. |

Remote Control |

|

Limit within 15m |

|

2. |

Foot-step Control |

|

2m line |

|

3. |

Wheels |

|

Need to be customized (considering load capacity and lifting height) |

|

4. |

Roller |

|

Need to be customized (considering the diameter of roller and gap) |

|

5. |

Safety Bellow |

|

Need to be customized (considering platform size and lifting height) |

|

6. |

Guardrails |

|

Need to be customized (considering platform size and height of guardrails) |

Features & Advantages

- Surface treatment: shot blasting and stoving varnish with anti-corrosion function.

- High quality pump station makes scissor lift table lifts and fall very stable.

- Anti-pinch scissor design; main pin-roll place adopts self-lubricating design which prolong life span.

- Removable lifting eye to help lift the table and install.

- Heavy duty cylinders with drainage system and check valve to stop the lift table dropping in case of hose burst.

- Pressure relief valve prevent overload operation; Flow control valve make descent speed adjustable.

- Equipped with aluminum safety sensor under the platform for anti-pinch while dropping.

- Up to American standard ANSI/ASME and Europe standard EN1570

- Safe clearance between scissor to prevent damages during operation.

- Brief structure make it much easier to operate and maintain.

- Stop at the per-concerted and accurate location point.

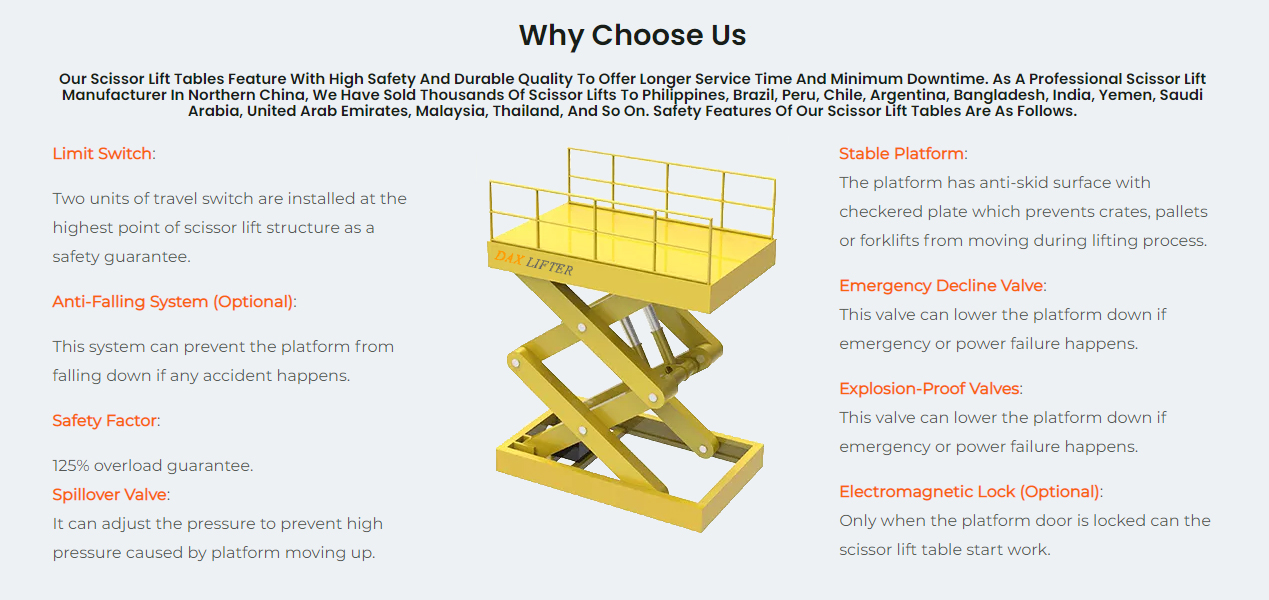

Safety Precautions

- Explosion-proof valves: protect hydraulic pipe, anti-hydraulic pipe rupture.

- Spillover valve: It can prevent high pressure when the machine moves up. Adjust the pressure.

- Emergency decline valve: it can go down when you meet an emergency or the power off.

- Overload protection locking device: in case of dangerous overload.

- Anti-dropping device: Prevent falling of platform.

- Automatic aluminum safety sensor: lift platform will stop automatically when come across barriers.