PriceList for Roller Conveyor Lift Table - Single Scissor Lift Table – Daxin

PriceList for Roller Conveyor Lift Table - Single Scissor Lift Table – Daxin Detail:

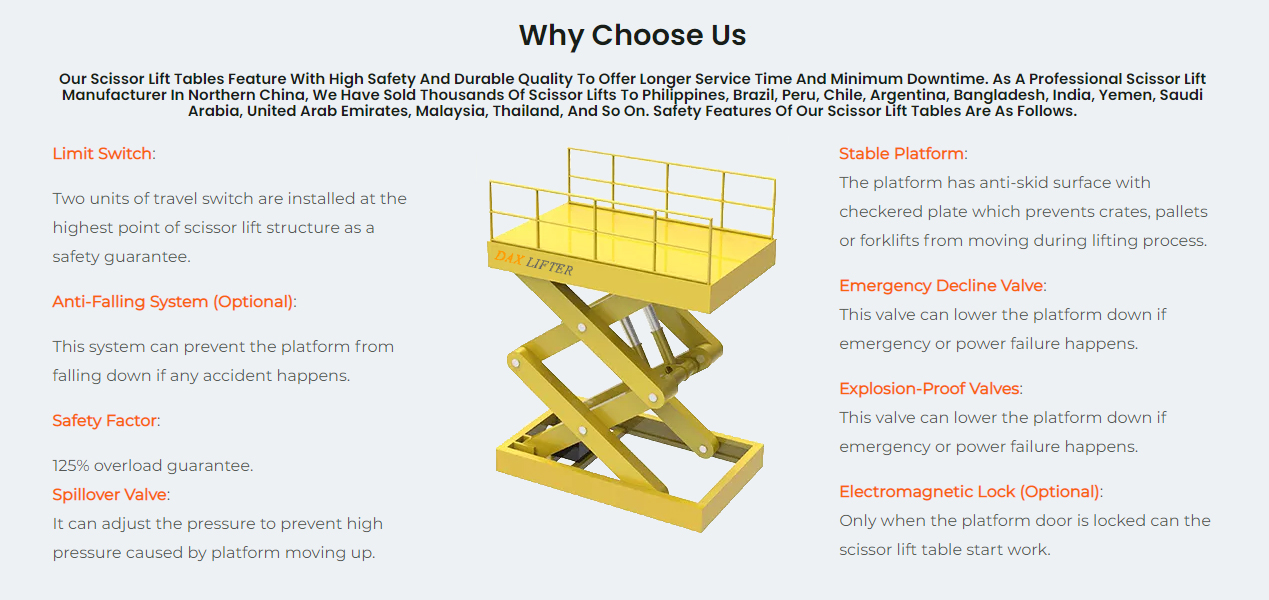

China Scissor Lift Table is popular in warehouse work and Automatic Conveyor work , there is many different type lift table offer to select.Besides,there is many installation method about how to install scissor lift platform,put it on ground directly or make a pit to become pit scissor lift table.

We have design many safety configuration for our Scissor Table Lift which include anti pinich function,overload protection,self lubricating bearings and safety below and so on. As a leading enterprise in China’s leading logistics handling industry, we are worthy of being trusted and chosen.Contact us to get a quotation which will satisfy you !

FAQ

Q: How about the quality of these scissor lift table?

A:Our scissor lift table has got ISO9001 and CE certificate already which is best quality lift table in China.We guarantee it can be used more than 10 years.

Q:Does the price of your lift table competitive?

A:Our scissor lift table adopt Standardized production which will reduce a lot of production cost.So our price will be so competitive,meanwhile guarantee quality of our scissor lift table.

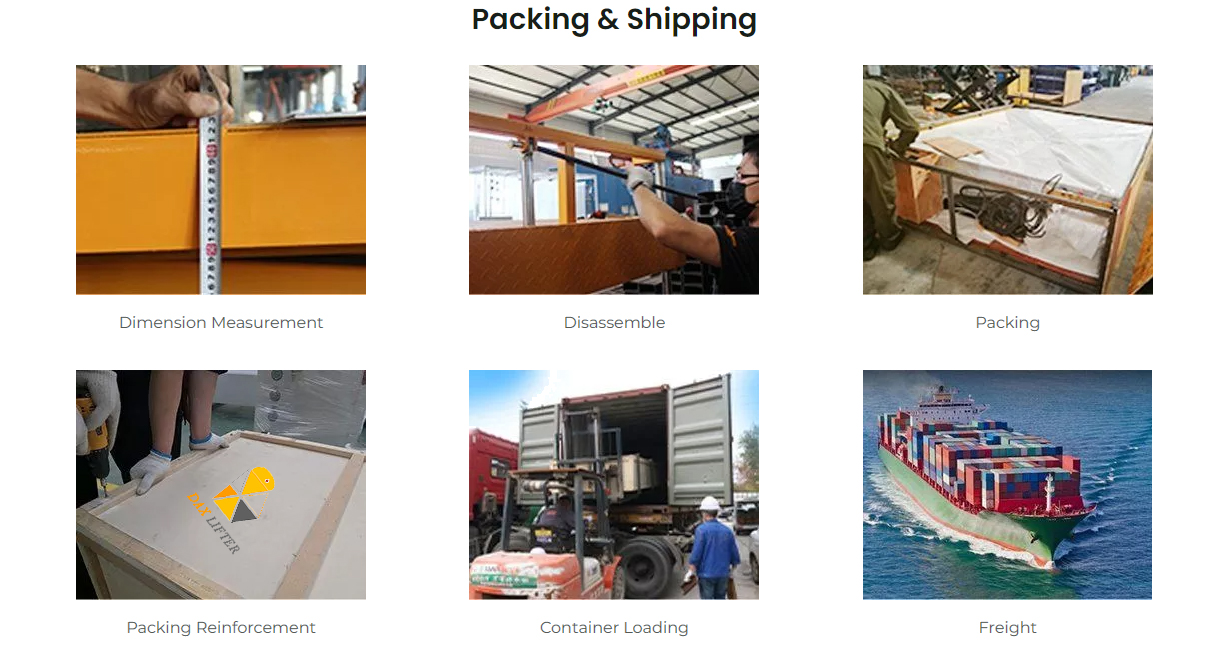

Q:How about your ability for shipping?

A:We have cooperated with powerful shipping company for many year who will offer economic shipping price to us and offer best shipping service.

Q:What is your warranty time?

A:We shall offer 12 months warranty time with free spare parts. Meanwhile offer long term technical support and charged parts once warranty time over.

Video

Specifications

|

Model |

Load Capacity (KG) |

Self Height (MM) |

Travel Height (MM) |

Platform Size(MM) L×W |

Base Size (MM) L×W |

Lifting time (S) |

Voltage (V) |

Motor (KW) |

Net weight (KG) |

||

|

1000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX1001 |

1000 |

205 |

1000 |

1300×820 |

1240×640 |

20~25 |

As per your request |

1.1 |

160 |

||

|

DX1002 |

1000 |

205 |

1000 |

1600×1000 |

1240×640 |

20~25 |

1.1 |

186 |

|||

|

DX1003 |

1000 |

240 |

1300 |

1700×850 |

1580×640 |

30~35 |

1.1 |

200 |

|||

|

DX1004 |

1000 |

240 |

1300 |

1700×1000 |

1580×640 |

30~35 |

1.1 |

210 |

|||

|

DX1005 |

1000 |

240 |

1300 |

2000×850 |

1580×640 |

30~35 |

1.1 |

212 |

|||

|

DX1006 |

1000 |

240 |

1300 |

2000×1000 |

1580×640 |

30~35 |

1.1 |

223 |

|||

|

DX1007 |

1000 |

240 |

1300 |

1700×1500 |

1580×1320 |

30~35 |

1.1 |

365 |

|||

|

DX1008 |

1000 |

240 |

1300 |

2000×1700 |

1580×1320 |

30~35 |

1.1 |

430 |

|||

|

2000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX2001 |

2000 |

230 |

1000 |

1300×850 |

1220×785 |

20~25 |

As per your request |

1.5 |

235 |

||

|

DX2002 |

2000 |

230 |

1050 |

1600×1000 |

1280×785 |

20~25 |

1.5 |

268 |

|||

|

DX2003 |

2000 |

250 |

1300 |

1700×850 |

1600×785 |

25~35 |

2.2 |

289 |

|||

|

DX2004 |

2000 |

250 |

1300 |

1700×1000 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DX2005 |

2000 |

250 |

1300 |

2000×850 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DX2006 |

2000 |

250 |

1300 |

2000×1000 |

1600×785 |

25~35 |

2.2 |

315 |

|||

|

DX2007 |

2000 |

250 |

1400 |

1700×1500 |

1600×1435 |

25~35 |

2.2 |

415 |

|||

|

DX2008 |

2000 |

250 |

1400 |

2000×1800 |

1600×1435 |

25~35 |

2.2 |

500 |

|||

|

4000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DX4001 |

4000 |

240 |

1050 |

1700×1200 |

1600×900 |

30~40 |

As per your request |

2.2 |

375 |

||

|

DX4002 |

4000 |

240 |

1050 |

2000×1200 |

1600×900 |

30~40 |

2.2 |

405 |

|||

|

DX4003 |

4000 |

300 |

1400 |

2000×1000 |

1980×900 |

35~40 |

2.2 |

470 |

|||

|

DX4004 |

4000 |

300 |

1400 |

2000×1200 |

1980×900 |

35~40 |

2.2 |

490 |

|||

|

DX4005 |

4000 |

300 |

1400 |

2200×1000 |

2000×900 |

35~40 |

2.2 |

480 |

|||

|

DX4006 |

4000 |

300 |

1400 |

2200×1200 |

2000×900 |

35~40 |

2.2 |

505 |

|||

|

DX4007 |

4000 |

350 |

1300 |

1700×1500 |

1620×1400 |

35~40 |

2.2 |

570 |

|||

|

DX4008 |

4000 |

350 |

1300 |

2200×1800 |

1620×1400 |

35~40 |

2.2 |

655 |

|||

Advantages

High-quality Surface Treatment:

In order to ensure the long service life of the equipment, the surface of our single scissor lift has been treated with shot blasting and baking paint.

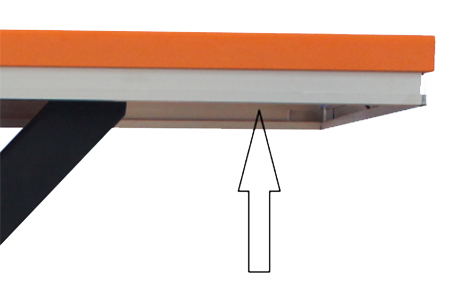

High-quality Hydraulic Power Unit:

Because our equipment uses high-quality pumping station units, the electric lift is more stable and safer during use.

Simple Structure:

Our equipment has a simple structure and it is easy to install.

Equipped With Flow Control Valve:

Lifting machinery is equipped with a flow control valve, which allows its speed to be controlled during the descending process.

Explosion-proof Valve Design:

In the design of the mechanical lifter, a protective hydraulic pipeline is added to prevent the hydraulic pipeline from rupturing.

Application

China Stationary Scissor Lift Table are widely used in various production workshops, assembly line production and warehouse handling industries.

Case 1:

Our New Zealand customer purchased our fixed lift table for the wood production line conveyor, and he chose a roller platform option, so that the wood can be transported down the production line more efficiently and conveniently. The option of Roller platform we can choose different sizes of rollers according to customer requirements to meet customer needs. In addition, he also chose foot control, because the workers are standing on a fixed position of the assembly line. Through the foot control, the workers can free their hands to operate the assembly line and adjust the wood on the assembly line.

Case 2:

Our Saudi Arabia customer purchases our electric lift table for the handling and loading and unloading of food warehouses. Through our hydraulic lift table, the food boxes are removed from the transport truck and the food boxes are loaded from the warehouse to the transport truck. Through our fixed scissor lift table, work efficiency can be improved and workers’ work easier.

Details

|

Control Handle Switch |

Automatic Aluminum Safety Sensor for Anti-pinch |

Electric Pump Station and Electric Motor |

|

|

|

|

|

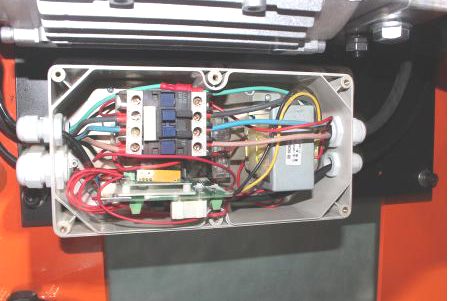

Electric Cabinet |

Hydraulic Cylinder |

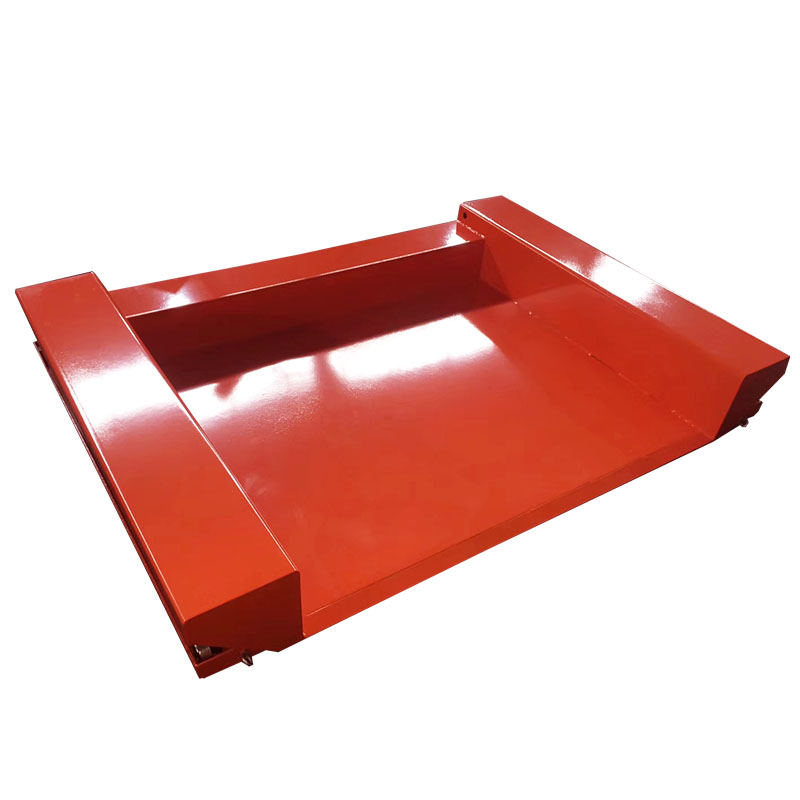

Package |

|

|

|

|

Product detail pictures:

Related Product Guide:

CAR LIFT STORAGE equipment is often used in some relatively large construction projects in addition to satisfying households, small auto repair shops, used car stores, 4S stores and personal households. Residential communities in some areas usually require acceptance before delivery, but the residential community may not be equipped with enough ground parking spaces or underground parking spaces. At this time, we can choose CAR LIFT STORAGE equipment to fill the parking spaces to ensure the government's acceptance and review of parking spaces. If the quantity is qualified, after acceptance, if the CAR LIFT STORAGE equipment is no longer needed, it can be dismantled for secondary sales or returned. Why can our CAR LIFT STORAGE equipment be used for work like this kind of project? Because our double-column style CAR LIFT STORAGE equipment can be installed in combination, this installation method can not only reduce the cost, but also be more firm. Because the multi-conjoined CAR LIFT STORAGE equipment has stronger stability. If you need. You can tell us your needs, and we will design one piece according to your actual site size. Our simple CAR LIFT STORAGE equipment has been tested by major testing institutions, and it can stand the test in terms of safety and work performance. Our CAR LIFT STORAGE equipment occupies a large market share especially in the European and North American markets. We also continue to cooperate with excellent distributors and terminal operators in these markets every year, and the annual sales can reach an ideal level. If you have CAR LIFT STORAGE equipment needs, please contact us. PriceList for Roller Conveyor Lift Table - Single Scissor Lift Table – Daxin , The product will supply to all over the world, such as: Mauritania, Nepal, Finland,

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!