OEM/ODM China Lifting Equipment - Vacuum Glass Lifter – Daxin

OEM/ODM China Lifting Equipment - Vacuum Glass Lifter – Daxin Detail:

|

Model Type |

DXGL-LD-350 |

DXGL-LD-600 |

DXGL-LD-800 |

|

|

Load Capacity |

350kg (retract)/175kg(extend) |

600kg (retract)/300kg(extend) |

800kg (retract)/400kg(extend) |

|

|

Lifting Height |

3650mm |

3650mm |

4500mm |

|

|

QTY of Suction Cap |

4pcs (standard) |

6pcs (standard) |

8pcs (standard) |

|

|

Suction Cap Diameter |

Ø300mm (standard) |

Ø300mm (standard) |

Ø300mm (standard) |

|

|

Battery |

2x12V/100AH |

2x12V/120AH |

2x12V/120AH |

|

|

Battery Charger |

Smart Charger |

Smart Charger |

Smart Charger |

|

|

Controller |

VST224-15 |

CP2207A-5102 |

VST224-1 |

|

|

Drive motor |

24V/600W |

24V/900W |

24V/1200W |

|

|

Hydraulic power |

24V/2000W/5L |

24V/2000W/5L |

24V/2000W/12L |

|

|

Front Wheel |

High elastic solid rubber wheel Ø310x100mm 2pcs |

High elastic solid rubber wheel Ø375x110mm 2pcs |

High elastic solid rubber wheel Ø300x125mm 2pcs |

|

|

Driving Wheel |

Ø250x80mm Middle horizontal drive wheel |

Ø310x100mmMiddle horizontal drive wheel |

Ø310x100mmMiddle horizontal drive wheel |

|

|

N.W/G.W |

780/820kg |

1200/1250kg |

|

|

|

Packing Size |

Wooden carton: 3150x1100x1860mm. (1x20GP Loading Qty: 5sets) |

|||

|

Movement |

Automatic (4 kinds) |

|

||

|

|

Manual (2kinds) |

|

||

|

Usages |

Special design for handling difference kind of heavy plate, such as steel, glass, granite, marble and so forth, with different materials of vacuum suction caps. | |||

Details

|

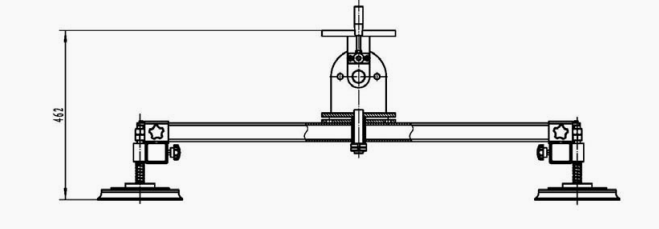

Drawing of 4pcs Suction Caps (DXGL-LD-350 Standard) |

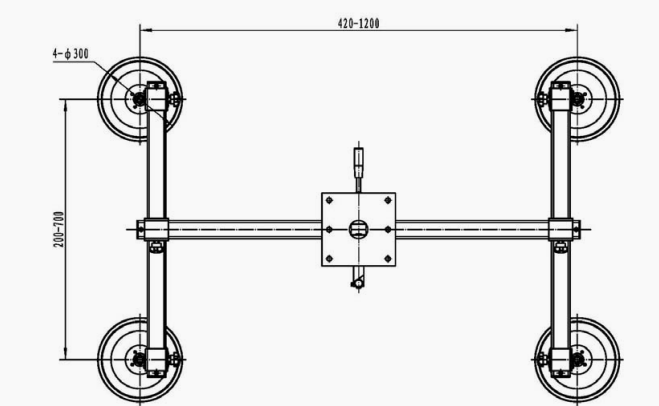

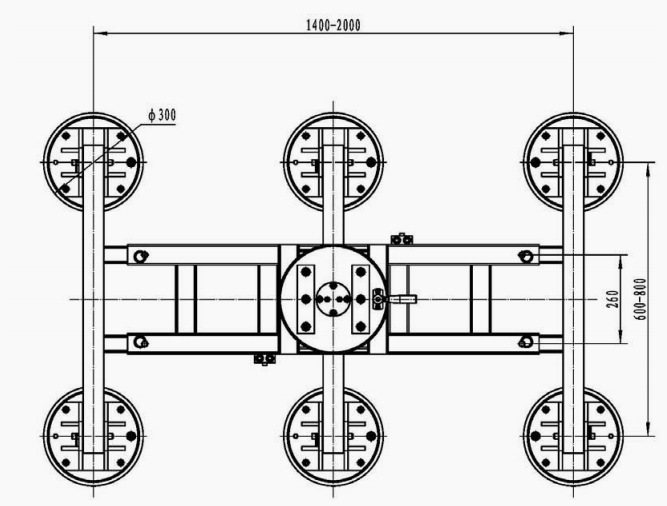

Drawing of 6pcs Suction Caps (DXGL-LD-600 Standard) |

|

|

|

|

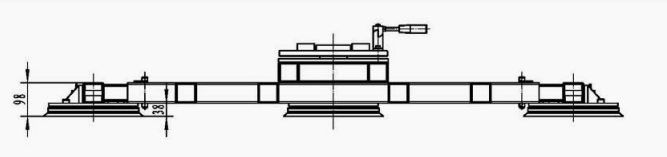

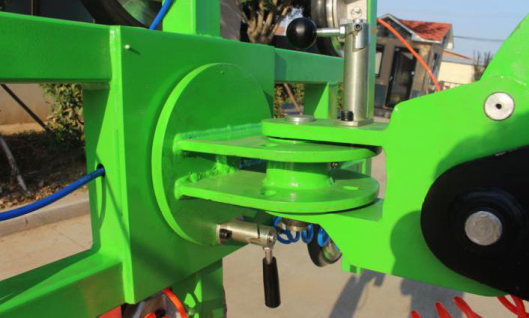

Adjustable Bracket: The bracket can be extended or retracted to fit for different size of heavy panel |

360degree Manual Rotation: Rotating and indexing locking pin |

|

|

|

|

Patented Suction Cap Assembly: strong and durable |

Rubber Suction Caps: to lift up heavy panels whose surface is smooth,like glass,marbles etc. |

|

|

|

|

Smart Driving Handle: forward/back knob,with belly switch and horn button.Easy to operate,very flexible. |

Main Power Switch and Battery Indicator |

|

|

|

|

Counter Weight: They keep balance the machine while loaded. 10pcs/15pcs.1pc is 20KG. |

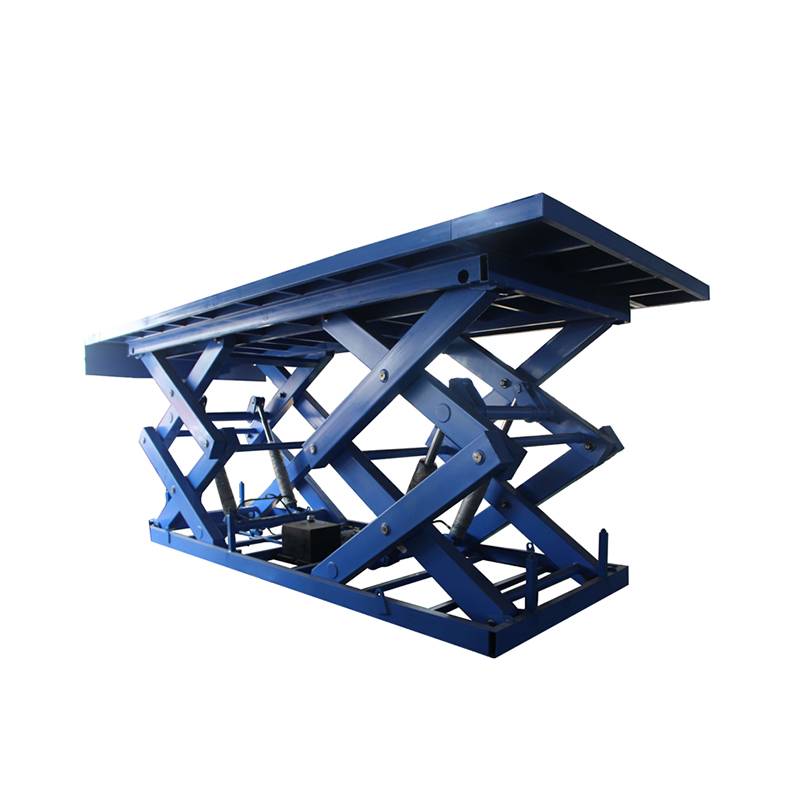

Strong Car Chassis: advanced rear axle drive and electromagnetic brakes. |

|

|

|

|

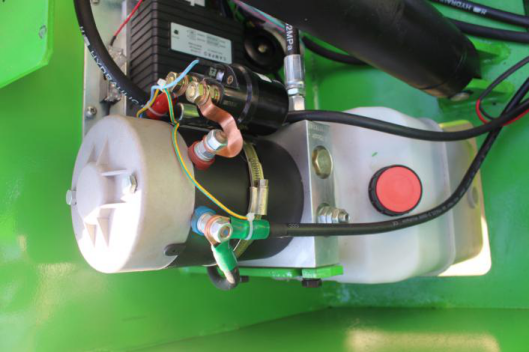

Maintenance Free Battery: with battery meter. Long life span for more than 5years. |

High Performance Pump Station and Oil Tank: with anti-explosion valve and over-flow valve for safety. |

|

|

|

|

Smart Hydraulic Controls: lift/lower/shaft left/right/retract/extended/tilt up/down etc. |

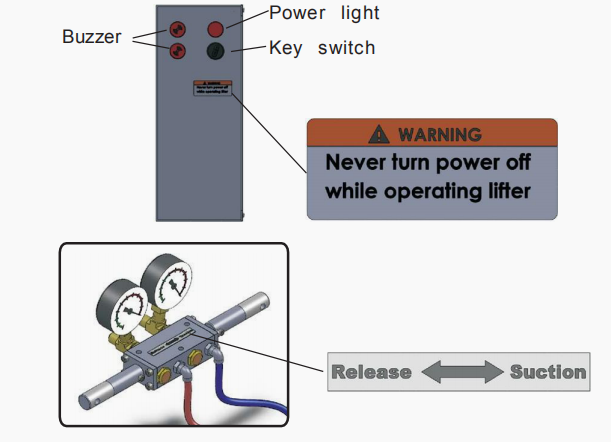

Smart Pneumatic Control: Power Switch and Buzzer |

|

|

|

|

Vacuum Gauge: the buzzer will keep alarming if the pressure is not proper. |

|

|

|

|

|

Main Hydraulic Boom and Extending Inner Boom |

Safety Precaution: in case of sudden fall and emergency decline needed |

|

|

|

|

Side Shaft Actuator and Battery Charger inside the front cover |

Electric Driving Wheel: rear axle drive and electromagnetic brake(250x80mm) |

|

|

|

|

Outriggers On Both Side (PU) |

Front Wheel (310x100mm) |

|

|

|

Product detail pictures:

Related Product Guide:

TRAILER MAN LIFT equipment is close to the extreme in the production process! Why do you say that? Because from the procurement of raw materials, product design and production process have adopted the world's top technology. Let us discuss these aspects separately. In the procurement of raw materials, we use the highest standard steel in China. High-strength steel can support the basic life of the equipment, which is the most important point for aerial work equipment. The quality and durability of the national standard steel have also reached the relevant world standards. In product design, after inspecting the equipment of relevant famous brands, our designers combined our own advantages and made the final design after numerous updates and improvements. These designs are based on the world's leading level and according to the market needs of different countries, we have also made targeted adjustments. So that TRAILER MAN LIFT equipment can adapt to different working environments, and can also bring the best quality experience to customers. What we need is not only a good aerial work equipment, but more importantly, customer approval. In the production process, we use a lot of high-tech means, such as CNC precision manufacturing, laser cutting, computer numerical control programming and so on. All welding adopts intelligent welding, which minimizes the working errors caused by manual welding. The overall production process uses automated equipment as much as possible, and at the same time reduces errors in each production link to the greatest extent possible. OEM/ODM China Lifting Equipment - Vacuum Glass Lifter – Daxin , The product will supply to all over the world, such as: Paraguay, Luxemburg, Rome,

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,