OEM China Container Load Lift Table - Roller Scissor Lift Table – Daxin

OEM China Container Load Lift Table - Roller Scissor Lift Table – Daxin Detail:

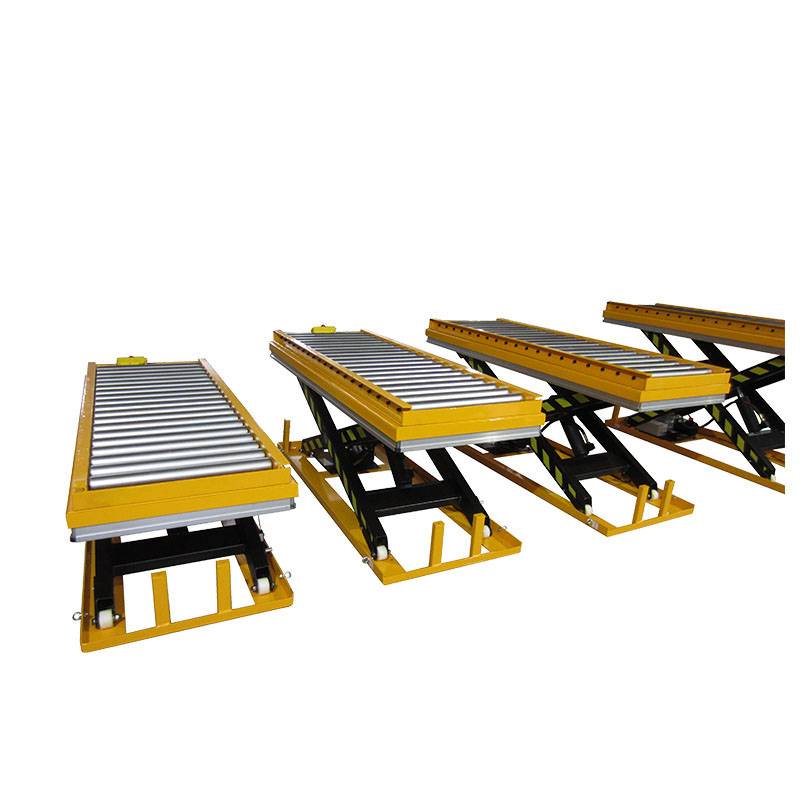

Roller scissor lift Table is suitable for assembly line work in factories and other industries.Mechanical equipment is a standard scissor lift. Roller equipment is equipped with safety valves: explosion-proof valve, overflow valve, emergency drop valve and other emergency operation buttons to fully protect the safety of goods and users. In addition to Roller hydraulic lift, we also have other scissor lifts, all of which can accept customized table tops and sizes.

Find the product you need, send an inquiry email to me, I will provide you with more detailed data.

FAQ

Q: What is the maximum capacity of the lift equipment?

A: The maximum load of the lift can reach 4000kg.

Q: How about the quality of these scissor lift table?

A: Our scissor lift table has got ISO9001 and CE certificate already which is best quality lift table in China.

Q: Does the price of your lift table competitive?

A: Our scissor lift tables adopt Standardized production which will reduce a lot of production cost. So our price will be so competitive, meanwhile guarantee quality of our scissor lift table.

Q: How about your ability for shipping?

A: We have cooperated with powerful shipping company for many year who will offer economic shipping price to us and offer best shipping service.

Video

Specifications

|

Model |

Load Capacity (KG) |

Self Height (MM) |

Travel Height (MM) |

Platform Size(MM) L×W |

Base Size (MM) L×W |

Lifting time (S) |

Voltage (V) |

Motor (KW) |

Net weight (KG) |

||

|

1000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DXR1001 |

1000 |

205 |

1000 |

1300×820 |

1240×640 |

20~25 |

As per your request |

1.1 |

160 |

||

|

DXR1002 |

1000 |

205 |

1000 |

1600×1000 |

1240×640 |

20~25 |

1.1 |

186 |

|||

|

DXR1003 |

1000 |

240 |

1300 |

1700×850 |

1580×640 |

30~35 |

1.1 |

200 |

|||

|

DXR1004 |

1000 |

240 |

1300 |

1700×1000 |

1580×640 |

30~35 |

1.1 |

210 |

|||

|

DXR1005 |

1000 |

240 |

1300 |

2000×850 |

1580×640 |

30~35 |

1.1 |

212 |

|||

|

DXR1006 |

1000 |

240 |

1300 |

2000×1000 |

1580×640 |

30~35 |

1.1 |

223 |

|||

|

DXR1007 |

1000 |

240 |

1300 |

1700×1500 |

1580×1320 |

30~35 |

1.1 |

365 |

|||

|

DXR1008 |

1000 |

240 |

1300 |

2000×1700 |

1580×1320 |

30~35 |

1.1 |

430 |

|||

|

2000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DXR2001 |

2000 |

230 |

1000 |

1300×850 |

1220×785 |

20~25 |

As per your request |

1.5 |

235 |

||

|

DXR2002 |

2000 |

230 |

1050 |

1600×1000 |

1280×785 |

20~25 |

1.5 |

268 |

|||

|

DXR2003 |

2000 |

250 |

1300 |

1700×850 |

1600×785 |

25~35 |

2.2 |

289 |

|||

|

DXR2004 |

2000 |

250 |

1300 |

1700×1000 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DXR2005 |

2000 |

250 |

1300 |

2000×850 |

1600×785 |

25~35 |

2.2 |

300 |

|||

|

DXR2006 |

2000 |

250 |

1300 |

2000×1000 |

1600×785 |

25~35 |

2.2 |

315 |

|||

|

DXR2007 |

2000 |

250 |

1400 |

1700×1500 |

1600×1435 |

25~35 |

2.2 |

415 |

|||

|

DXR2008 |

2000 |

250 |

1400 |

2000×1800 |

1600×1435 |

25~35 |

2.2 |

500 |

|||

|

4000Kg Load Capacity Standard Scissor Lift |

|||||||||||

|

DXR4001 |

4000 |

240 |

1050 |

1700×1200 |

1600×900 |

30~40 |

As per your request |

2.2 |

375 |

||

|

DXR4002 |

4000 |

240 |

1050 |

2000×1200 |

1600×900 |

30~40 |

2.2 |

405 |

|||

|

DXR4003 |

4000 |

300 |

1400 |

2000×1000 |

1980×900 |

35~40 |

2.2 |

470 |

|||

|

DXR4004 |

4000 |

300 |

1400 |

2000×1200 |

1980×900 |

35~40 |

2.2 |

490 |

|||

|

DXR4005 |

4000 |

300 |

1400 |

2200×1000 |

2000×900 |

35~40 |

2.2 |

480 |

|||

|

DXR4006 |

4000 |

300 |

1400 |

2200×1200 |

2000×900 |

35~40 |

2.2 |

505 |

|||

|

DXR4007 |

4000 |

350 |

1300 |

1700×1500 |

1620×1400 |

35~40 |

2.2 |

570 |

|||

|

DXR4008 |

4000 |

350 |

1300 |

2200×1800 |

1620×1400 |

35~40 |

2.2 |

655 |

|||

Advantage

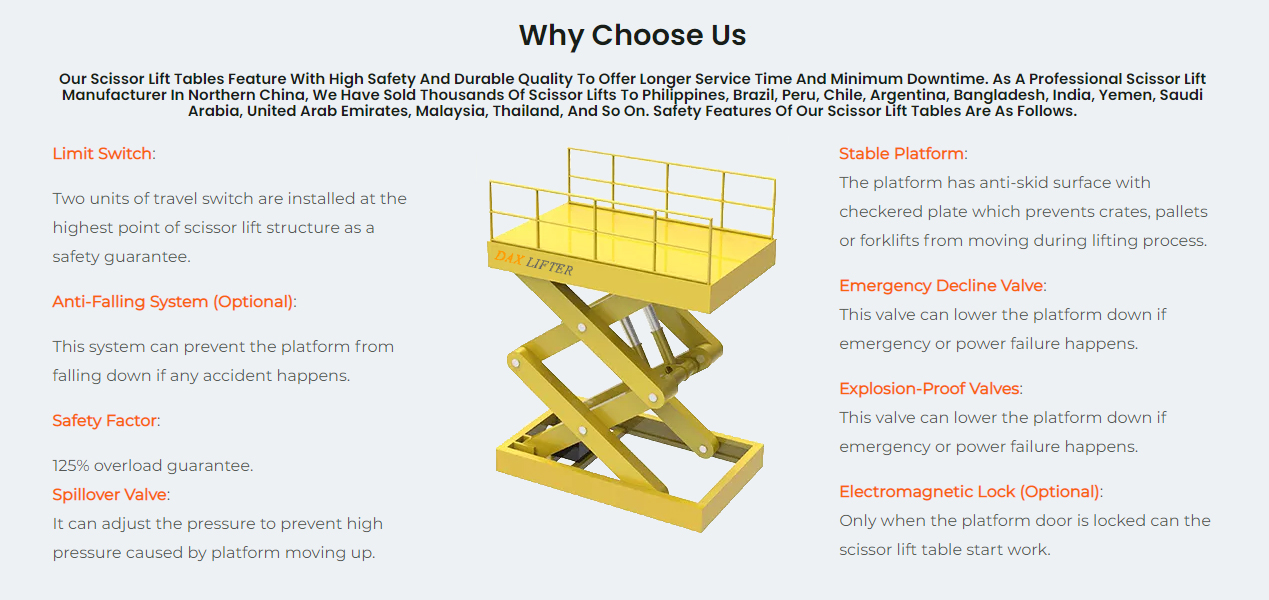

Emergency drop valve:

In the process of work, when there is an emergency or a power outage, the scissor lift can also be lowered.

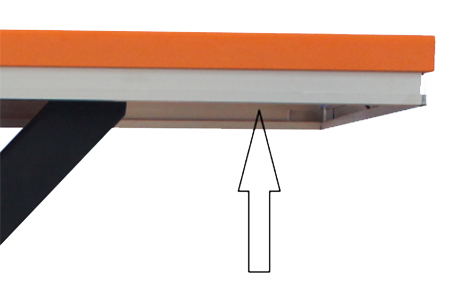

Aluminum safety sensor:

When the platform is raised and lowered, it will automatically stop when it encounters an obstacle.

Spillover valve:

To prevent the equipment from generating high pressure during the ascent process, adjust the pressure.

Surface treatment:

The surface of the equipment has been treated with shot blasting and baking paint, which has anti-corrosion function.

Simple structure:

The structure of the roller elevator is relatively simple, and the installation process is easier

Application

Case 1

One of our French customers bought our products for the production line in his processing plant. The table surface of the equipment is designed with rollers, so it is easier to operate on the assembly line. Because it is more convenient for his workers to sit and operate, we recommend that he be equipped with a foot controller, which can free the workers’ hands to do other tasks. After customers apply our products to production, it greatly improves the efficiency of the factory.

Case 2

One of our Irish customers bought our Roller Scissor Lift for the circulation of products in his supermarket. The table surface of the equipment is designed with rollers. This design can easily transfer heavy products to a fixed location, greatly reducing the workload of the staff, and they can do more relaxed work. The application of the machinery lift improves the efficiency of transferring goods in the supermarket. The customer is very confident in the quality of our products, and once again purchased 5 sets of equipment for his supermarket to transfer goods.

Details

|

Control Handle Switch |

Automatic Aluminum Safety Sensor for Anti-pinch |

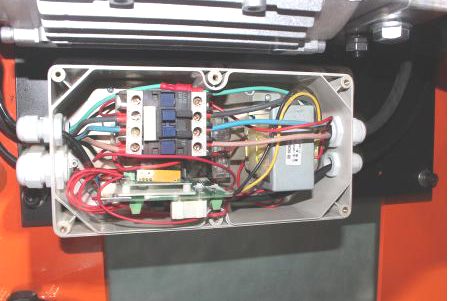

Electric Pump Station and Electric Motor |

|

|

|

|

|

Electric Cabinet |

Hydraulic Cylinder |

Package |

|

|

|

|

Product detail pictures:

Related Product Guide:

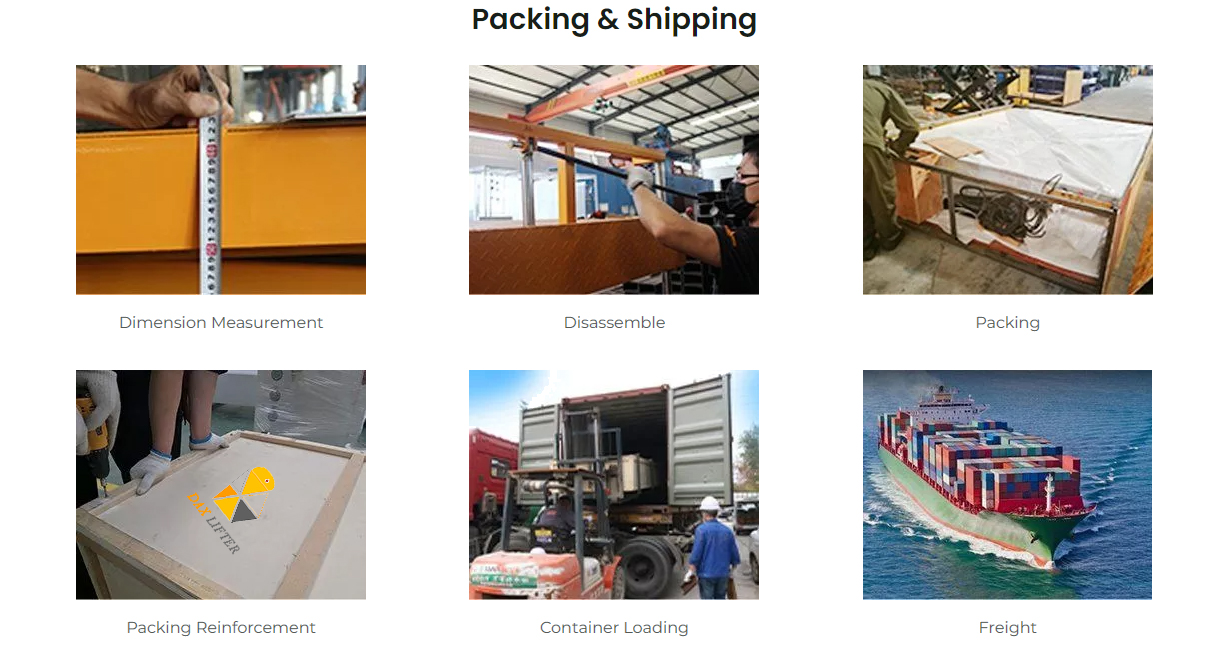

GLASS VACUUM LIFTER equipment is mainly used for handling and installing glass panels, suitable for various glass panel factories, home improvement companies and warehouse glass panel handling and other work. However, we can change the material of the suction cup so that our GLASS VACUUM LIFTER equipment can absorb and handle more materials, such as marble slab, granite slab, iron plate, steel plate and so on. But there is a point of knowledge that is particularly important here, that is, the sheets of various materials that are adsorbed cannot leak. If air leakage occurs, a vacuum state cannot be formed in the suction cup at all, which makes the suction cup unable to absorb. Many customers do not understand this point, and we always try our best to explain it. There are basically two types of suction cups, sheet suction cups and glass suction cups. Glass suction cups usually use rubber suction cups, and sheet suction cups usually use sponge suction cups. For the sponge suction cup, the suction cup of this material can also absorb the uneven surface of the flat plate, because the sponge is flexible, it can automatically fill the sponge into the uneven recessed position when the vacuum machine starts to work. Only after this process can the uneven sheet be successfully lifted up by adsorption. OEM China Container Load Lift Table - Roller Scissor Lift Table – Daxin , The product will supply to all over the world, such as: Australia, Kuwait, Portugal,

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.