Lift Tables For Pallets - Manufacturers, Factory, Suppliers from China

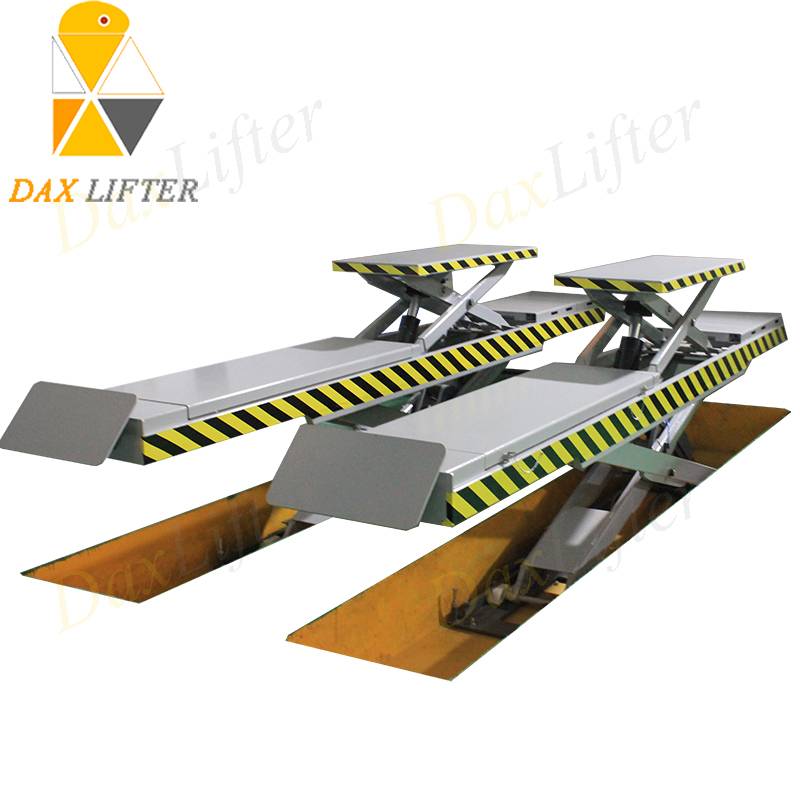

Scissor lift platform is the crawler-type aerial work equipment suitable for use on construction sites. Crawler-type design structure enables the equipment to have a larger contact area with the ground and has stronger grip ability, making it easy and safe to cross rough, uneven or muddy roads. Scissor lift platform has the function of automatic walking. Only one person can operate the machine to continuously complete lifting, forward, backward, steering and other actions during high-altitude work, which is very flexible and convenient. Scissor lift platform crawler design structure can improve the climbing ability of the equipment, so that it can climb the slope smoothly. In order to ensure that workers have a larger aerial work surface, the extension platform unlocked by foot can be quickly rolled out to the working point, which greatly expands the working area in the air. At the same time, working at heights is more dangerous than working on the ground. In order to reduce the risk of work and better protect the staff, the fence plays a good role in safety protection. Scissor lift platform type high-altitude scissor type machinery has a larger carrying capacity, and can accommodate multiple workers to work at the same time in the work site, which can speed up the progress of building construction. Lift Tables For Pallets, Motorbike Lift, Car Service Lift, Electric Scissor Lift,Aerial Man Lift. The product will supply to all over the world, such as Europe, America, Australia,Namibia, Florida,azerbaijan, Chile.

Related Products