Hydraulic Drive Scissor Lift

DAXLIFTER China Scissor Lift self propelled hydraulic driving type widely use in aerial work platform Industry.Usually the mobile scissor lift works in aerial installation,aviation industry and aerial repair work.For supporting these work ,there is also multiple Aerial Scissor Liftoffer to select to suit for different job.The best advantage of Self propelled scissor lift compare with manual moving mobile scissor lift is that people or worker can stand on the top platform control moving of scissor lift which is more convenient, but manual moving hydraulic scissor lift have to make the platform go down, then close the support leg to let it go another work place.Meanwhile,the whole configuration of self moving scissor lift use many imports parts from famous brand which will make the working life of electric scissor lift longer and stable.Contact us to get a quotation if you want to know more specifications!

FAQ

A: Our scissor lift has passed the global quality system certification and obtained the European Union's audit certification. The quality is absolutely free of any problems and very durable. High stability.

A: Our products adopt a standardized production model, and have established multiple assembly lines, using a large number of automation equipment, automatic welding robots and other equipment to reduce production costs. So our price is very advantageous.

A: We have cooperated with professional shipping companies for many years. They provide us with the cheapest prices and the best service. So our ocean shipping capabilities are very good.

A: We provide 12 months of free warranty, and if the equipment is damaged during the warranty period due to quality problems, we will provide customers with free accessories and provide necessary technical support. After the warranty period, we will provide lifetime paid accessories service.

Video

Applications

China hydraulic self-propelled scissor lift is a very important equipment in the aerial work industry. You can see the mobile scissor lift in large-scale construction sites or on the construction site of road administration facilities.

Case 1:

Our Argentina customer purchases our scissor car to go back to the high-altitude pipeline maintenance of the oil refinery. The worker drives the scissor lift to shuttle between the various pipes. Because this self moving scissor lift is self-propelled type, there is no need to repeatedly open and retract the outriggers. This can save a lot of working time. And our scissor aerial platform is equipped with an extension platform, which can extend the horizontal working range. Compared with self-propelled boom lift lifting equipment, the advantage of the scissor lift platform is that it is more economical and has a larger work surface, which can carry more workers on it. Now the configuration and quality of our scissor lift supplier are very high, and can support customers' work for many years through upgrades and updates. Durable and stable.

Case 2:

Our Korean customer bought our scissor car and used it for the line maintenance and installation of the power plant. For this reason, we specially customized the insulation platform for customers, and carried out explosion-proof treatment on all electrical components to ensure the safety of the equipment. Now this Korean customer is ready to purchase our scissor cart again.

Specifications

|

Model No. |

DX06 |

DX08 |

DX10 |

DX12 |

|

Lifting Height (mm) |

6000 |

8000 |

10000 |

12000 |

|

Working Height(mm) |

8000 |

10000 |

12000 |

14000 |

|

Lifting capacity |

300 |

300 |

300 |

300 |

|

Folding maximum height-guardrail unfolding (mm) |

2150 |

2275 |

2400 |

2525 |

|

Folding maximum height-guardrail removed (mm) |

1190 |

1315 |

1440 |

1565 |

|

Overall Length (mm) |

2400 |

|||

|

Overall Width (mm) |

1150 |

|||

|

Platform Size (mm) |

2270×1150 |

|||

|

Platform extend size (mm) |

900 |

|||

|

Minimum ground clearance-folding (mm) |

110 |

|||

|

Minimum ground clearance-rising (mm) |

20 |

|||

|

Wheelbase (mm) |

1850 |

|||

|

Minimum turn radius-inner wheel (mm) |

0 |

|||

|

Minimum turn radius-outer wheel (mm) |

2100 |

|||

|

Running speed-folding (km/h) |

4 |

|||

|

Running speed-rising (km/h) |

0.8 |

|||

|

Rising/falling speed (sec) |

40/50 |

70/80 |

||

|

Battery (V/AH) |

4×6/210 |

|||

|

Charger (V/A) |

24/25 |

|||

|

Maximum climbing ability (%) |

20 |

|||

|

Maximum working allowable angle |

2-3° |

|||

|

Way of control |

Electro-hydraulic proportion control |

|||

|

Driver |

Double front-wheel |

|||

|

Hydraulic drive |

Double rear-wheel |

|||

|

Wheel size-stuffed&no mark |

Φ381×127 |

Φ381×127 |

Φ381×127 |

Φ381×127 |

|

Whole weight (kg) |

1900 |

2080 |

2490 |

2760 |

Details

|

America CUITIS Electric Control Handle on the Platform |

Foldable Guardrails with Automatic Lock Gate |

Extendable Platform 900mm |

|

|

|

|

|

High Strength Scissors,Produced by Rectangle Tubes |

Italy Hydrappp Hydraulic Pump Station and Italy Doyle Hydraulic Valve |

Firm and Durable Chassis with Tilt Sensor Alarm |

|

|

|

|

|

America TORJAN Battery Group and Shanghai SHINENG Intelligent Charger |

Battery Charger Hole |

A.Control Panel on Chassis |

|

|

|

|

|

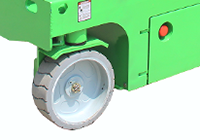

America White Non-marking PU Driving Wheels |

Power Switch |

Spray Paint Treatment Anti-corrosion |

|

|

|

|

Folding guardrails

Multi-function control handle

Anti-skidding platform

Extendable platform

Automatic lock gate

High strength scissors

Durable hydraulic cylinder

Stable hydraulic pump station

Hydraulic drive motor

Non-marking PU driving wheels

Pot hole automatic protection system

Automatic brakes system

Emergency stop button

Emergent descent valve

Automatic diagnostic indicator

Tilt sensor alarm

Siren

Safety brackets

Forklift hole

Intelligent battery charger

High capacity battery

Features & Advantages:

1. The product is controlled based on the imported intelligent technology.

2. It is powered by DC, can be controlled by manually. It can move automatically and the moving speed is adjustable.

3. It can climb a gradient very well.

4. The recharge will restrict the rising of the platform.

5. The driving motor has the automatic braking function.

6. The emergent drop will be locked.

7. The malfunction can be diagnosed automatically and the maintenance is very convenient.

Safety Precautions:

1. Explosion-proof valves: protect hydraulic pipe, anti-hydraulic pipe rupture.

2. Spillover valve: It can prevent high pressure when the machine moves up. Adjust the pressure.

3. Emergency decline valve: it can go down when you meet an emergency or the power off.

4. Anti-dropping device: Prevent falling of platform