Hot New Products Hydraulic Lifting Equipment - Glass Suction Cup Lifter Manufacturer With CE Approved – Daxin

Hot New Products Hydraulic Lifting Equipment - Glass Suction Cup Lifter Manufacturer With CE Approved – Daxin Detail:

Glass suction cup lifter is a mobile equipment specially designed for handling different types of thick plates, plates, and glass. Vacuum suction cup can be used to absorb and install steel plates, glass walls, granite, marble and other materials by adjusting the material of the suction cups. The use of vacuum suction cups and its powerful drive system can easily handle raw materials related to lifting, moving and rotating.

In order to meet the requirements of working in different environments, we have designed vacuum lifter for different purposes. Send inquiry to us for more detailed parameters.

Video

FAQ

Q: What’s the loading capacity of the glass suction cup lifter?

A: Its loading capacity range is 400kg-800kg.

Q: How is the quality of your Glass Suction Cup Lifter?

A: Our products have been certified by the European Union, so please feel free to inquire and purchase products.

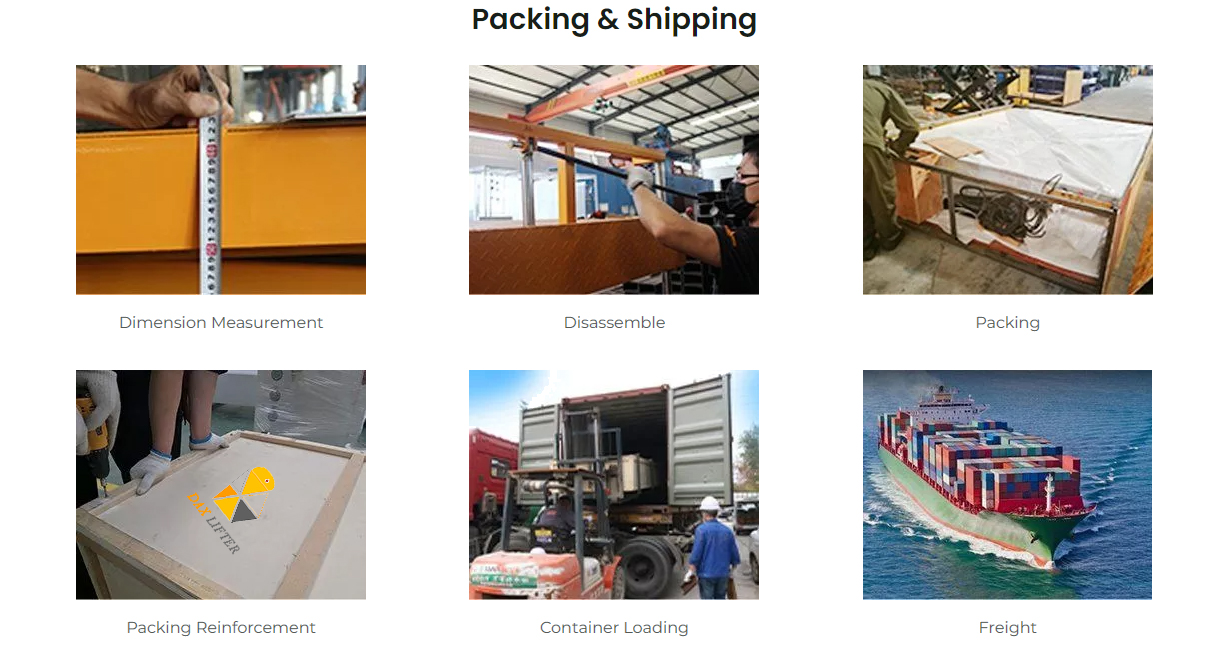

Q: How is your shipping capacity?

A: We have cooperated with many professional shipping companies for many years, and they will provide us with very good services in terms of ocean transportation.

Q: How do we send an inquiry to your company?

A: Both the product page and the homepage have our contact information. You can click the button to send an inquiry or contact us directly: sales@daxmachinery.com Whatsapp:+86 15192782747

DXGL-HD-40 Series

|

Model |

DXGL-HD-4015(4×30) |

DXGL-HD-4015(6×25) |

DXGL-HD-4015(6×30) |

DXGL-HD-4015(8×25) |

|

Max. Load Capacity |

400kgs |

400kgs |

400kgs |

400kgs |

|

Safe Load Capacity |

200kgs |

200kgs |

200kgs |

200kgs |

|

Lifting Height |

1500mm |

1500mm |

1500mm |

1500mm |

|

QTY of Caps (customized) |

4pcs |

6pcs |

6pcs |

8pcs |

|

Cap Diameter |

Ø300mm |

Ø250mm |

Ø300mm |

Ø250mm |

| Plate Size (customized) |

1220x1830mm |

1220x1830mm |

1220x1830mm |

1220x1830mm |

|

Load Center |

650mm |

650mm |

650mm |

650mm |

|

Drive Motor |

24V/500W |

24V/500W |

24V/500W |

24V/500W |

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

24V/2000W |

24V/2000W |

|

Battery |

2x12V/70Ah |

2x12V/70Ah |

2x12V/70Ah |

2x12V/70Ah |

|

Charger |

24V/10A |

24V/10A |

24V/10A |

24V/10A |

DXGL-HD-60 Series

|

Model |

DXGL-HD-6015(4×30) |

DXGL-HD-6015(6×25) |

DXGL-HD-6015(6×30) |

DXGL-HD-6015(8×30) |

|

Max. Load Capacity |

600kgs |

600kgs |

600kgs |

600kgs |

|

Safe Load Capacity |

300kgs |

300kgs |

300kgs |

300kgs |

|

Lifting Height |

1500mm |

1500mm |

1500mm |

1500mm |

|

QTY of Caps (customized) |

4pcs |

6pcs |

6pcs |

8pcs |

|

Cap Diameter |

Ø300mm |

Ø250mm |

Ø300mm |

Ø300mm |

| Plate Size (customized) |

2440x1830mm |

2440x1830mm |

2440x1830mm |

2440x1830mm |

|

Load Center |

950mm |

950mm |

950mm |

950mm |

|

Drive Motor |

24V/700W |

24V/700W |

24V/700W |

24V/700W |

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

24V/2000W |

24V/2000W |

|

Battery |

2x12V/100Ah |

2x12V/100Ah |

2x12V/100Ah |

2x12V/100Ah |

|

Charger |

24V/15A |

24V/15A |

24V/15A |

24V/15A |

A.DXGL-HD-80 Series

|

Model |

DXGL-HD-8015(6) |

DXGL-HD-8015(8) |

DXGL-HD-8015(10) |

DXGL-HD-8025(8) |

DXGL-HD-8025(10) |

|

Max. Load Capacity |

800kgs |

800kgs |

800kgs |

800kgs |

800kgs |

|

Safe Load Capacity |

400kgs |

400kgs |

400kgs |

400kgs |

400kgs |

|

Lifting Height |

1500mm |

1500mm |

1500mm |

2500mm |

2500mm |

|

QTY of Caps (customized) |

6pcs |

8pcs |

10pcs |

8pcs |

10pcs |

|

Cap Diameter |

Ø300mm |

Ø300mm |

Ø300mm |

Ø300mm |

Ø300mm |

| Plate Size (customized) |

3660x2440mm |

3660x2440mm |

3660x2440mm |

3660x2440mm |

3660x2440mm |

|

Load Center |

1250mm |

1250mm |

1250mm |

1250mm |

1250mm |

|

Drive Motor |

24V/900W |

24V/900W |

24V/900W |

24V/900W |

24V/900W |

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

24V/2000W |

24V/2000W |

24V/2000W |

|

Battery |

2x12V/160Ah |

2x12V/160Ah |

2x12V/160Ah |

2x12V/160Ah |

2x12V/160Ah |

|

Charger |

24V/20A |

24V/20A |

24V/20A |

24V/20A |

24V/20A |

Why Choose Us

As a professional vacuum glass lifter supplier, we have provided professional and safe lifting equipment to many countries around the world, including the United Kingdom, Germany, the Netherlands, Serbia, Australia, Saudi Arabia, Sri Lanka, India, New Zealand, Malaysia, Canada and others nation. Our equipment takes into account the affordable price and excellent work performance. In addition, we can also provide perfect after-sales service. There is no doubt that we will be your best choice!

Different vacuum pump:

According to the material of the suction cup, the appropriate vacuum pump is configured to ensure work safety.

Large rotation angle:

Standard configuration manual flip 0°-90°, manual rotation 0-360°.

Extended arm:

When the glass size is larger, you can choose to install an extension arm.

Self-propelled drive:

It can self-propelled drive, which is more convenient to move.

Optional suction cup material:

According to the different objects that need to be sucked up, you can choose suckers of different materials.

Balance Weight Machine:

It can ensure that the front and rear weights are balanced during the work process to ensure the safety of work.

Advantages

Check valve:

The one-way valve used in conjunction with the accumulator can prevent accidental power failure during the use of the suction crane, and can keep the workpiece in the adsorbed state for 5-30 minutes without falling;

Energy storage device:

In the entire absorption process, the existence of the accumulator ensures that the vacuum system has a certain degree of vacuum. When an emergency occurs, such as a sudden power failure, the glass can still maintain the adsorption state with the spreader for a long time without falling off, which can effectively protect the operator.

Manually turn the suction cup:

Manually flip and rotate suction cup, which is more convenient to adjust the appropriate angle.

Different swept volume:

The swept volume of rubber sucker is 30L. The swept volume of sponge sucker is 200L.

Different gas tank:

According to the different position of different compartments to confirm the capacity, rubber sucker use small gas tank 0.5L. However, the sponge sucker will use big gas tank 5L~10L.

Application

Case 1

Our Italian customers buy our glass suction cup lifter for high-altitude glass installation. The main purpose of the customer buying the lifter is to absorb the glass to facilitate work, so the material of the suction cup is silica gel, and the adsorption is firmer during the working process to ensure a safe working environment.

Case 2

A customer in Brazil bought our glass suction cup lifter to assist in the suction of wooden boards. We changed the material of the suction cup to a sponge, so that the suction is firmer during the work process, ensuring a safe working environment. Because the weight of the wood board is not particularly heavy, the customer customized the load-bearing capacity of 400kg, and the highly customized one is 2.5m high for work.

Product detail pictures:

Related Product Guide:

Narrow scissor lift design concept is to create a high-altitude work platform with compact structure, flexible operation and high utilization rate. Compact structure allows narrow scissor lift to be applied in many crowded and narrow working environments, such as maintenance of indoor lines, picking up goods on high shelves or painting walls, etc. The use of narrow scissor lift can make the work of the staff more safe and efficient. If you need to go to different workplaces, the mobile device is also very convenient. Its design structure has a forklift hole, which can be easily transported to a truck and moved to different locations. Narrow scissor lift is installed with an intelligent and flexible operating system. Compared with manual scissor lift, with narrow scissor lift, workers can easily control the platform, automatically lift the platform and move the position, as long as the narrow scissor lift is on a flat road, it can drive freely. The platform is designed with a 0.55m extension platform, which is more convenient for high-altitude work. If there is an uneven position on the ground or some small obstacles, narrow scissor lift cannot accurately move to the working position. At this time, this is where the extended table comes into play; it can stretch over small obstacles to help expand the workplace of workers, so that workers can easily complete high-altitude work. Hot New Products Hydraulic Lifting Equipment - Glass Suction Cup Lifter Manufacturer With CE Approved – Daxin , The product will supply to all over the world, such as: Algeria, Brunei, Irish,

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.