2020 wholesale price Hydraulic Pallet Lifter - Vacuum Glass Lifter – Daxin

2020 wholesale price Hydraulic Pallet Lifter - Vacuum Glass Lifter – Daxin Detail:

Vacuum suction cup machine is mainly suitable for the installation or transportation of glass, wood, cement and iron plates. The difference from the glass suction cup is that the sponge suction cup needs to be replaced to absorb other materials. Automatic glass loading machine is equipped with an adjustable bracket that can be extended to adapt to panels of different sizes. If you don’t need to the mobile machine, we also have the separate suction cup, which can be transported directly with a hook. More glass lifter can be searched on the homepage, or you can directly contact us to recommend your product. Our contact information can be obtained on the “Contact Us” page.

Video

FAQ

Q: What does the vacuum sucker rely on to drive the equipment?

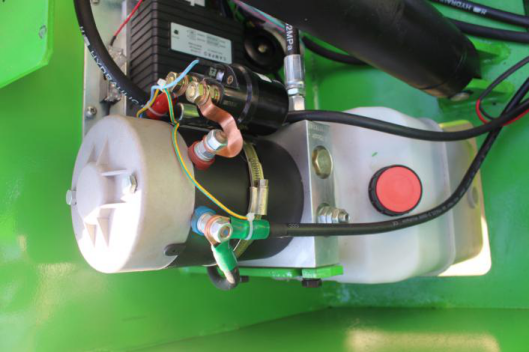

A: The suction cup is driven by a battery, which avoids cable entanglement and is more convenient to use.

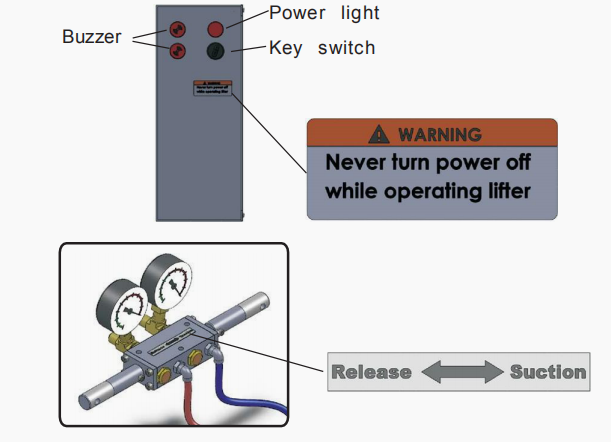

Q: Will the glass fall when the power is suddenly cut off during work?

A: No, our equipment is equipped with an accumulator to ensure that the vacuum system has a certain degree of vacuum. In the case of a sudden power failure, the glass can still maintain the adsorption state with the spreader and will not fall off, which can effectively protect the operator.

Q: What is the maximum height of the vacuum lifter?

A: Our maximum height can be customized to 4500 mm.

Q: Can I easily trust the quality of your products?

A: Yes, we have passed the European Union certification, and the quality is guaranteed.

Applications

Case 1

One of our Singaporean customers equipped his decoration company with 2 vacuum suction cup lifts, which are used by workers when installing glass, which greatly improves work efficiency and can also provide on-site service to more of his customers. Our customer has a good experience and decided to buy 5 vacuum lifts again so that his workers can go to different places to install the glass.

Case 2

One of our Turkish customers bought our vacuum suction cups and used them as rental equipment in his equipment rental company. At that time, our communication and service were well recognized by our customers. The customer first bought two sets of vacuum glass machines and rented them back. However, his customers generally reported that they were very practical and he was very satisfied with our products and services, so they repurchased 10 equipment is used for rental.

Specifications

|

Model Type |

DXGL-LD-350 |

DXGL-LD-600 |

DXGL-LD-800 |

|

|

Load Capacity |

350kg (retract)/175kg(extend) |

600kg (retract)/300kg(extend) |

800kg (retract)/400kg(extend) |

|

|

Lifting Height |

3650mm |

3650mm |

4500mm |

|

|

QTY of Suction Cap |

4pcs (standard) |

6pcs (standard) |

8pcs (standard) |

|

|

Suction Cap Diameter |

Ø300mm (standard) |

Ø300mm (standard) |

Ø300mm (standard) |

|

|

Battery |

2x12V/100AH |

2x12V/120AH |

2x12V/120AH |

|

|

Battery Charger |

Smart Charger |

Smart Charger |

Smart Charger |

|

|

Controller |

VST224-15 |

CP2207A-5102 |

VST224-1 |

|

|

Drive motor |

24V/600W |

24V/900W |

24V/1200W |

|

|

Hydraulic power |

24V/2000W/5L |

24V/2000W/5L |

24V/2000W/12L |

|

|

Front Wheel |

High elastic solid rubber wheel Ø310x100mm 2pcs |

High elastic solid rubber wheel Ø375x110mm 2pcs |

High elastic solid rubber wheel Ø300x125mm 2pcs |

|

|

Driving Wheel |

Ø250x80mm Middle horizontal drive wheel |

Ø310x100mmMiddle horizontal drive wheel |

Ø310x100mmMiddle horizontal drive wheel |

|

|

N.W/G.W |

780/820kg |

1200/1250kg |

|

|

|

Packing Size |

Wooden carton: 3150x1100x1860mm. (1x20GP Loading Qty: 5sets) |

|||

|

Movement |

Automatic (4 kinds) |

|

||

|

|

Manual (2kinds) |

|

||

|

Usages |

Special design for handling difference kind of heavy plate, such as steel, glass, granite, marble and so forth, with different materials of vacuum suction caps. | |||

Details

|

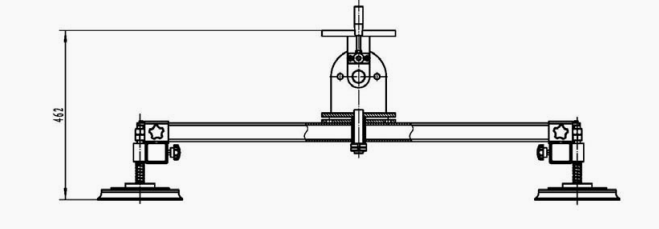

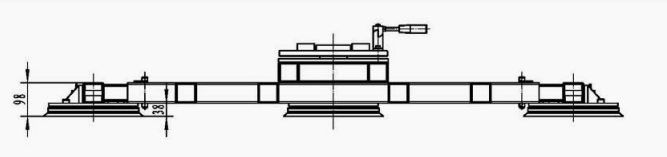

Drawing of 4pcs Suction Caps (DXGL-LD-350 Standard) |

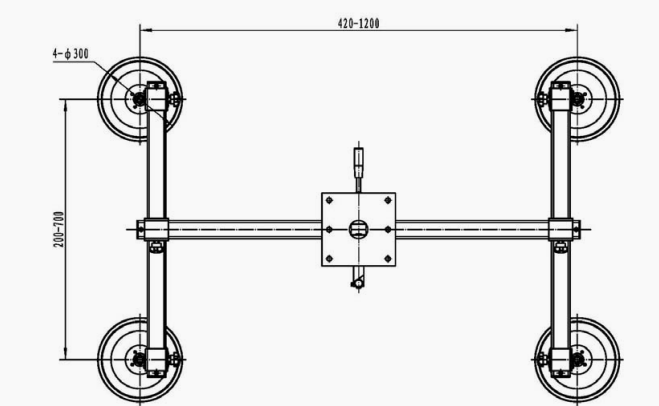

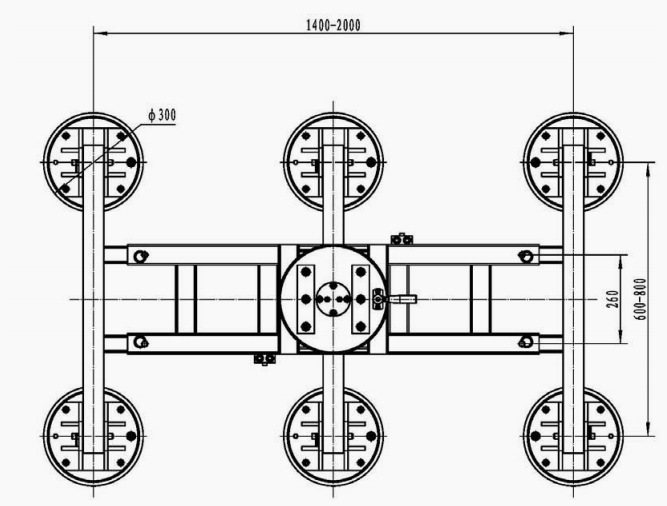

Drawing of 6pcs Suction Caps (DXGL-LD-600 Standard) |

|

|

|

|

Adjustable Bracket: The bracket can be extended or retracted to fit for different size of heavy panel |

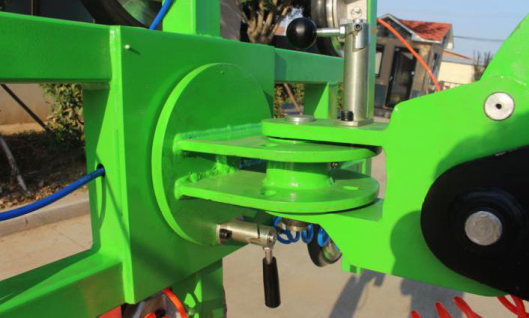

360degree Manual Rotation: Rotating and indexing locking pin |

|

|

|

|

Patented Suction Cap Assembly: strong and durable |

Rubber Suction Caps: to lift up heavy panels whose surface is smooth,like glass,marbles etc. |

|

|

|

|

Smart Driving Handle: forward/back knob,with belly switch and horn button.Easy to operate,very flexible. |

Main Power Switch and Battery Indicator |

|

|

|

|

Counter Weight: They keep balance the machine while loaded. 10pcs/15pcs.1pc is 20KG. |

Strong Car Chassis: advanced rear axle drive and electromagnetic brakes. |

|

|

|

|

Maintenance Free Battery: with battery meter. Long life span for more than 5years. |

High Performance Pump Station and Oil Tank: with anti-explosion valve and over-flow valve for safety. |

|

|

|

|

Smart Hydraulic Controls: lift/lower/shaft left/right/retract/extended/tilt up/down etc. |

Smart Pneumatic Control: Power Switch and Buzzer |

|

|

|

|

Vacuum Gauge: the buzzer will keep alarming if the pressure is not proper. |

|

|

|

|

|

Main Hydraulic Boom and Extending Inner Boom |

Safety Precaution: in case of sudden fall and emergency decline needed |

|

|

|

|

Side Shaft Actuator and Battery Charger inside the front cover |

Electric Driving Wheel: rear axle drive and electromagnetic brake(250x80mm) |

|

|

|

|

Outriggers On Both Side (PU) |

Front Wheel (310x100mm) |

|

|

|

Product detail pictures:

Related Product Guide:

MOBILE ORDER PICKER equipment is a material handling equipment that is popular all over the world, and you can almost see him in any large warehouse. Shelves in warehouses are usually very high. If the MOBILE ORDER PICKER equipment is not used, the workers cannot reach the high-rise goods, so the MOBILE ORDER PICKER equipment is designed. Why is MOBILE ORDER PICKER equipment specially designed for warehouse cargo handling? First of all, the MOBILE ORDER PICKER equipment adopts a self-propelled control method, that is to say, workers can stand on the table and drive the MOBILE ORDER PICKER equipment to shuttle between the shelves like a vehicle. This control method greatly improves work efficiency. In the warehouse, the transmission ladder or scaffolding is still used as a solution to pick up the goods. This kind of work efficiency is very low. The use of MOBILE ORDER PICKER equipment can maximize the work efficiency. After a long calculation, it is very important to use the budget to buy MOBILE ORDER PICKER equipment. Cost-effective. In addition, MOBILE ORDER PICKER equipment also specially designed a workbench for placing goods. In this way, while taking the goods, it can provide space for the goods to be placed. without affecting the worker's standing position. And, the guardrail of MOBILE ORDER PICKER equipment is also carefully designed. The guardrails on both sides can be opened so that when workers face the shelves on the side, it is necessary to cross the guardrails to take the goods and it is dangerous. The battery, controller, pump station and other important components of the MOBILE ORDER PICKER equipment are all made of well-known brands, durable and have excellent working performance. The battery capacity can support a whole day of work after one full charge. If the frequency of use is not particularly high, it can be supported. Three to five working days. Peace of mind and convenience. 2020 wholesale price Hydraulic Pallet Lifter - Vacuum Glass Lifter – Daxin , The product will supply to all over the world, such as: United Arab Emirates, Japan, Bangkok,

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.