2020 China New Design Inclined Disable Lift - Vertical Wheelchair Lift – Daxin

2020 China New Design Inclined Disable Lift - Vertical Wheelchair Lift – Daxin Detail:

|

Model Type |

VWL2510 |

VWL2515 |

VWL2520 |

VWL2525 |

VWL2530 |

VWL2535 |

VWL2540 |

VWL2550 |

VWL2560 |

|

Max. Platform Height |

1000mm |

1500mm |

2000mm |

2500mm |

3000mm |

3500mm |

4000mm |

5000mm |

6000mm |

|

Load Capacity |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

250kg |

|

N.W/G.W(kg) |

350/450 |

450/550 |

550/700 |

700/850 |

780/900 |

850/1000 |

880/1050 |

1000/1200 |

1100/1300 |

|

Machine Size(mm) |

2000*1430*1300 |

2500*1430*1300 |

3000*1430*1000 |

3500*1430*1000 |

4000*1430*1000 |

4600*1430*1000 |

5100*1430*1000 |

6100*1430*1000 |

7100*1430*1000 |

|

Packing Size(mm) |

2200*1600*1600 |

2700*1600*1600 |

3200*1600*1600 |

3700*1600*1600 |

4200*1600*1600 |

4800*1600*1600 |

5300*1600*1600 |

6300*1600*1600 |

7300*1600*1600 |

|

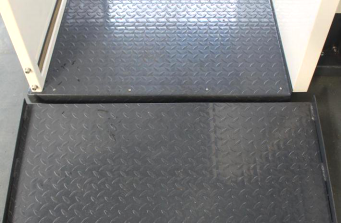

Platform size |

1430*1000mm skid proof checkered steel |

||||||||

|

Min Platform height |

60mm |

||||||||

|

Speed |

0.06~0.1m/s |

||||||||

|

Control voltage |

24V/DC |

||||||||

|

Power Output |

1.1~2.2KW |

||||||||

|

Voltage |

As per your local Standard(single phase or three phase) |

||||||||

|

Drive System |

Hydraulic pump station and electric motor (See details below) |

||||||||

|

Control Mode |

Automatic travel switch(See details below) |

||||||||

|

Drive Control |

Self-resetting system |

||||||||

|

Overload |

Over current relay protection |

||||||||

|

Materials |

Aluminium rails and guard with spraying plastics. (See details below) |

||||||||

|

Working Condition |

Both indoors and outdoors -20°~70°C |

||||||||

|

Entrance-Exit Way |

It’s customized 90°or 180° |

||||||||

|

Installation |

No pit installing,easy to install and remove <3.0m,installed directly on the floor. >3.0m, installed both on the floor and on the wall. |

||||||||

|

Switches (See details below) |

|

||||||||

|

20’ Container Load |

2pcs |

2pcs |

1pc |

1pc |

1pc |

1pc |

1pc |

/ |

/ |

|

40’ Container Load |

4pcs |

4pcs |

3pcs |

3pcs |

2pcs |

2pcs |

2pcs |

1pc |

1pc |

Details

|

Switch 1: Control panel on platform |

Switch 2: Remote control |

|

|

|

|

Switch 3: Two column control: one is on ground floor; another can be fixed at any floor needed. |

Two Travel Switches.One plays an important role of slow down while approaching the ground. The other one cut off the power when reach the bottom. |

|

|

|

|

Whole aluminum rails. All refined aluminum parts are produced by mould,rather than rude welded iron. |

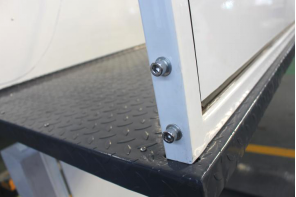

All bolts and screws are stainless steel,being used to assemble and fix each parts together |

|

|

|

|

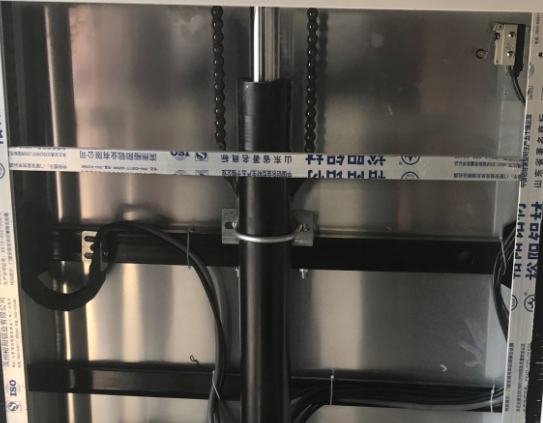

Hydraulic Pump Station and Electric Motor |

Strengthening Ribs,to fix the cylinder and reinforce the whole structure |

|

|

|

|

Up converter:Rise slowly and keep steady during operation. |

The protection Chain. Helping up-down,keep balance and maintain steady,protecting the safety of a suddenly drop. |

|

|

|

|

Safety Sensor. During the falling,it will stop if there are object below. |

Safety Sensor. During the falling,it will stop if there are object below. |

|

|

|

|

Emergency Decline Bar |

Electric Magnetic Valve. Pull the “manual down”to go down through”Emergency Decline Bar” control the electric magnetic valve. |

|

|

|

|

Optional Ramp fixed on the ground,static |

Optional Automatic Ramp, up and down with the car automatically |

|

|

|

|

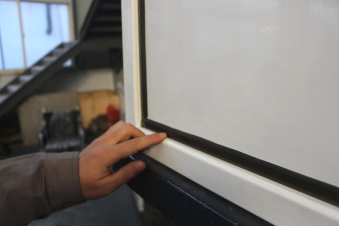

Japan Seal. It ensure the close fitting,more durable |

Slide Block: Nylon-antifraying,good noise reduction |

|

|

|

|

Fixed Structure,strong and durable enough |

Supporting Legs,keep balance |

|

|

|

|

Hydraulic Pump Station and Electric Motor |

Strengthening Ribs,to fix the cylinder and reinforce the whole structure |

Product detail pictures:

Related Product Guide:

ELECTRIC SCISSOR LIFT TABLE optional functions are very complete, including roller platforms, organ covers, remote control handles, optional wheels, adding guardrails, adding loading and unloading ramps, etc. The option of the roller platform is often used in some wood processing factories, furniture processing factories and assembly line operations. By choosing drums with different diameters to match different production line types, we can also provide customized electric rotating drums for some customer needs. These aspects are very convenient for customers. The function of the organ cover is mainly to use the organ cover to enclose the scissor structure. In this way, workers and other foreign objects can be protected to the greatest extent from entering the scissor structure. It can well protect the safety of ELECTRIC SCISSOR LIFT TABLE equipment and workers. The function of the remote control handle is relatively simple. It is suitable for customers who need to operate at a distance. When the ELECTRIC SCISSOR LIFT TABLE platform carries some dangerous items, the staff cannot approach it. Therefore, choosing a remote control handle can protect workers to the greatest extent. Some customers also choose wheels on the light ELECTRIC SCISSOR LIFT TABLE equipment, so that the ELECTRIC SCISSOR LIFT TABLE equipment can be pushed away directly when the working position needs to be changed. The installation of the guardrail is determined according to the customer's goods. If the size of the goods to be loaded by the customer is relatively high, we will recommend adding guardrails to ensure the stability of the goods. The ramp is installed to facilitate the pallet truck to drag the goods onto the platform. 2020 China New Design Inclined Disable Lift - Vertical Wheelchair Lift – Daxin , The product will supply to all over the world, such as: Libya, Uruguay, Angola,

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.